Bioprinting breakthrough: New method may allow 3-D printing of human organs

News and Tribune

A recent breakthrough in 3-D printing could spell life for the thousands of patients in the U.S. every year who await heart and other organ transplants.

Until now, 3-D printing has been restricted to creating hard materials using thin layers of plastic or metal. However, materials scientists hope one day to be able to print living things, such as working hearts, for people in need of transplants or reconstructive surgery. That would require being able to 3-D print soft materials, which until recently was impossible.

A team of researchers at Carnegie Mellon University led by Adam Fineberg, associate professor of Materials Science and Biomedical Engineering, tackled this problem and devised a way to use a special gel to layer soft material. The group published its findings in the October 23 issue of the journal Science Advances.

“The challenge with soft materials – think about something like Jello that we eat – is that they collapse under their own weight when 3-D printed in air," explained Professor Feinberg. "So we developed a method of printing these soft materials inside a support bath material. Essentially, we print one gel inside of another gel, which allows us to accurately position the soft material as it's being printed, layer by layer.”

Bioprinting thus far has been conducted only on costly proprietary machines built in a lab or purchased for “hundreds of thousands of dollars,” Feinberg said. The Carnegie Mellon team used off-the-shelf 3-D printers and open-source software. The approach allowed for greater control of print parameters and reduced the cost of printing equipment to about $1,000 per machine, meaning that this technique, once perfected, might be readily available at the consumer level.

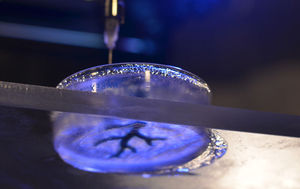

The method is relatively simple. A petri dish filled with the support material is placed in the printer and the printer uses a syringe to dispense the soft material. The support gel holds the soft material in place so the syringe can accurately place each new layer. Once the printer is finished, the petri dish is heated to human body temperature, around 99 degrees Fahrenheit, and the support gel liquefies, allowing for the safe removal of the printed material.

While this is an amazing start, the team still has a lot of work to do before they will be able to print living, beating hearts.

“What we’re doing now is focusing on heart tissue,” Feinberg explained. “What we’re trying to do is also now integrate cardiac myocytes, which are heart muscle cells, into those tissue constructs as we’re printing them.”