Is 3D printed bacteria the future of electronics?

The article was originally published on 3dprintingindustry.com.

Wearable tech is the name given to smart electronic devices that can be worn or implanted in the body. An enticing opportunity for innovative tech developers in sports, health, fashion and entertainment, 3D printing is revealing new possibilities for wearable tech such as electronic second skins, and smart fabrics.

In the latest research from Massachusetts Institute of Technology (MIT), a team has developed a “living” 3D printer bio-ink that’s not only smart but could change the way we think about technology altogether. Harnessing natural reactions of bacteria, responsive devices made using this smart ink represent the basic build blocks of electricity-free wearable tech.

Made by members of the same team that made the soft-robotic, fish-catching glove, this 3D printable bio-ink adds to an extensive portfolio of smart materials in development at MIT.

3D printing and programming genetically engineered bacteria

This MIT materials study was led by Prof Xuanhe Zhao and Dr. Timothy Lu of the Soft Active Materials Laboratory. As a proof-of-concept, the researchers and their team demonstrate how live 3D printed bacteria bio-ink containing bacteria can be programmed to light up when it receives a particular chemical signal.

First, the ink is prepared with ingredients to make it the perfect microenvironment for living matter. To a hydrogel base, the researchers add a photo-initiator so the material can be cured, along with bacterial cell pellets, bacterial feed, and deionized water.

In preparation, it was also essential for the team to sel ect the appropriate bacteria, as previous attempts using other cells had failed. “It turns out those cells were dying during the printing process because mammalian cells are basically lipid bilayer balloons,” explains Hyunwoo Yuk, one of the study’s co-authors, “they are too weak, and they easily rupture.”

Bacterial cells were chosen because their protective cell walls can withstand the pressures of 3D printing and thrive inside aqueous hydrogels. The bacteria were biologically engineered to emit green fluorescent proteins (GFPs), either in their normal state or when activated by a particular chemical signal.

3D printing complex living structures with the living ink

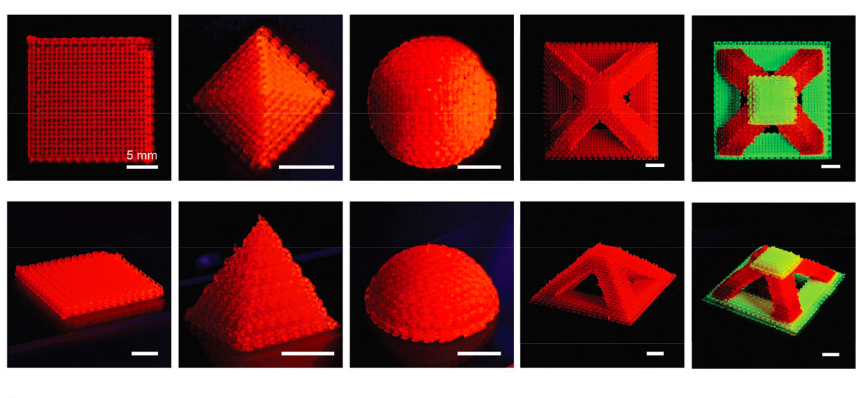

In the first example, researchers 3D printed complex macroscopic structures (3 cm) with microscopic precision (30 μm).

These included a square, a solid pyramid, a hollow pyramid and a dome. The elaborate structures were designed with SOLIDWORKS or CADfusion, sliced and 3D printed with a three-axis robotic deposition stage from Aerotech at room temperature in air.

The hydrogel inks were extruded fr om a UV-blocking 5 mL syringe barrel through nozzles with a diameter ranging between 30 and 200 μm.

The ink was initially 3D printed in a physically cross-linking matrix. This design was critical to ensure the viability and responsiveness of cells in living networks. Chemical cross-linking was then achieved by exposing the 3D printed hydrogel inks to UV light. The cross-linked hydrogel inks were kept in humid conditions thereafter.

To demonstrate how different signaling chemicals could activate the GFPs in different parts of the shape, the researchers 3D printed the pyramid using two different strains of the genetically engineered bacteria for different parts.

When exposed to a particular signaling chemical, the top, and base if the hollow pyramid turned a fluorescent green, while the sides of the shape remained red.

3D printed living tattoos

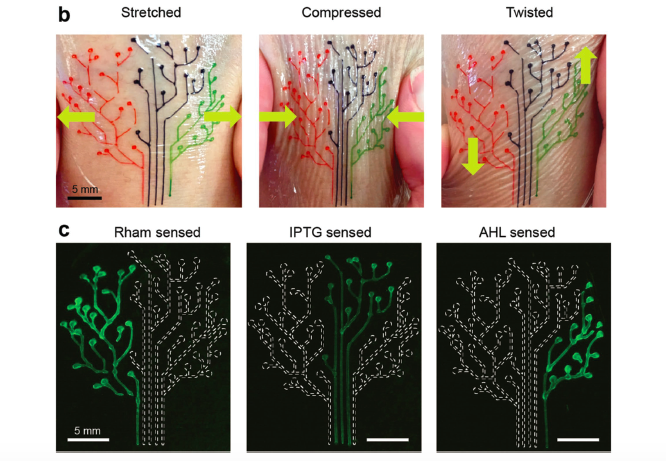

In a second example three hydrogel inks, each with a different strain of bacteria, were 3D printed as a “living tattoo” to detect the presence of different signaling chemicals on the skin.

The tattoo was printed with live bacteria cells in a tree-like pattern on a thin elastomer layer. It was then stuck on to a human test subject’s skin.

Three branches of the tree were 3D printed with different strains of the live bacteria, which would react to different signaling chemicals. Over several hours, branches of the patch’s tree lit up when bacteria sensed their corresponding chemical stimuli on the skin.

Possible computing applications of the 3D printed hydrogel inks

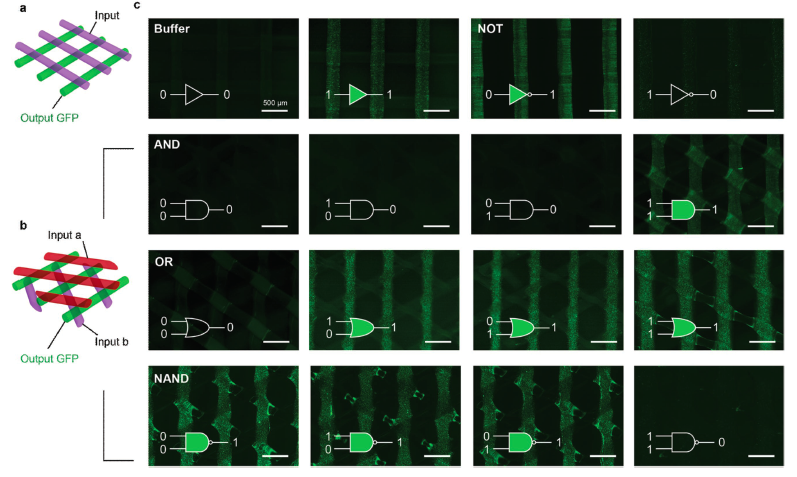

A third possible of the 3D printed hydrogel inks is in computational operations. Instead of the interactions between electronic components on a computer chip, interactions between the cells and chemicals can be programmed like logic gates or boolean operators.

The lines of ink were positioned in such a way so that instead of an electronic input, the absence or presence of active components corresponds to an input value of 0 or 1 respectively. Likewise, the absence or presence of GFP production corresponds to an output value of 0 or 1. In this way, the material can be programmed.

“Each cell in the structure performs a simple computational operation,” Liu explained to Nanowerk. “However, combined with their spatial distributions in the 3D architectures, the interactions among different cell types and chemicals in different regions can induce the emergence of informative patterns and achieve complex logic operations.”

From the smart mechanical to the smart biological

In addition to its applications in logic gates and chemical detection, the 3D printed living bio-ink also has medical applications.

“We can use bacterial cells like workers in a 3D factory,” said Liu. “They can be engineered to produce drugs within a 3D scaffold, and applications should not be confined to epidermal devices. As long as the fabrication method and approach are viable, applications such as implants and ingestibles should be possible.”

The full paper, “3D Printing of Living Responsive Materials and Devices”, is published online in the journal Advanced Materials. It is co-authored by Xinyue Liu, Hyunwoo Yuk, Shaoting Lin, German Alberto Parada, Tzu-Chieh Tang, Eléonore Tham, Cesar de la Fuente-Nunez, Timothy K. Lu, and Xuanhe Zhao.