Tissue 3D printing expedited with finer in air microfluidics at twente

The article was originally published on 3dprintingindustry.com.

3D printing is instrumental in next generation pharmaceuticals and regenerative medicine. The flexibility of the technique allows it to be used in a number of ways fr om providing the perfect microenvironment for living cells, to microfluidic chips ideal for testing and creating new chemical compounds.

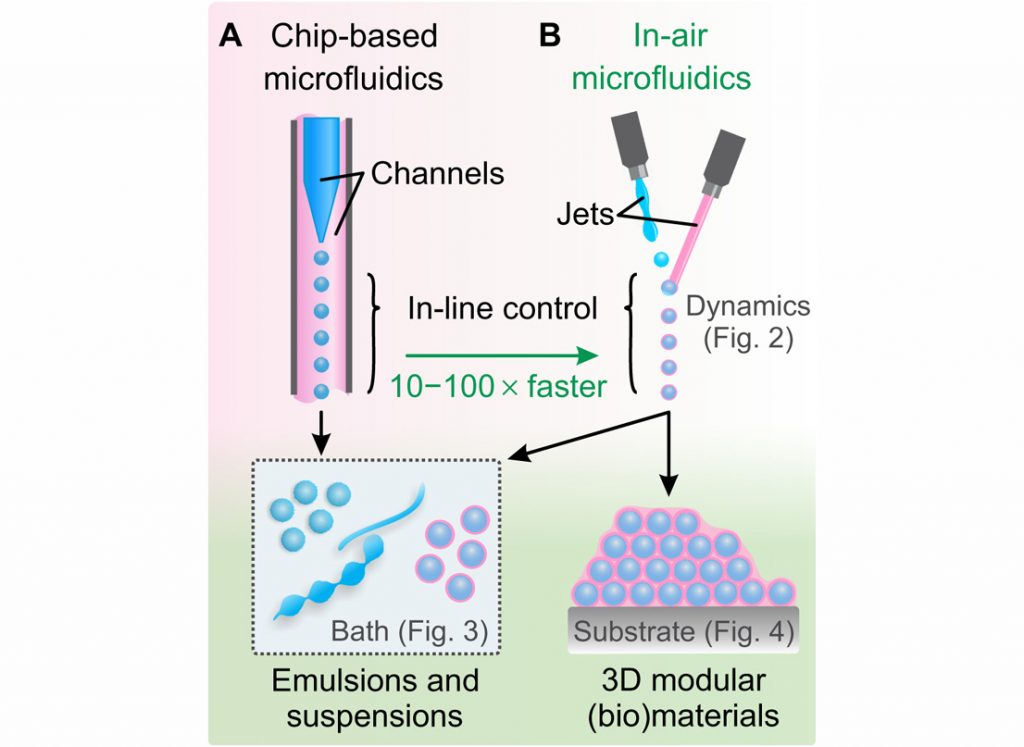

However, a team at the University of Twente (UT), the Netherlands, noticed some shortcomings in conventional medical 3D printing techniques. In a method termed “in-air microfluidics” the UT team have developed a new, and entirely unique 3D bioprinting system that works by colliding particles in the air.

Pottery plus 3D printing

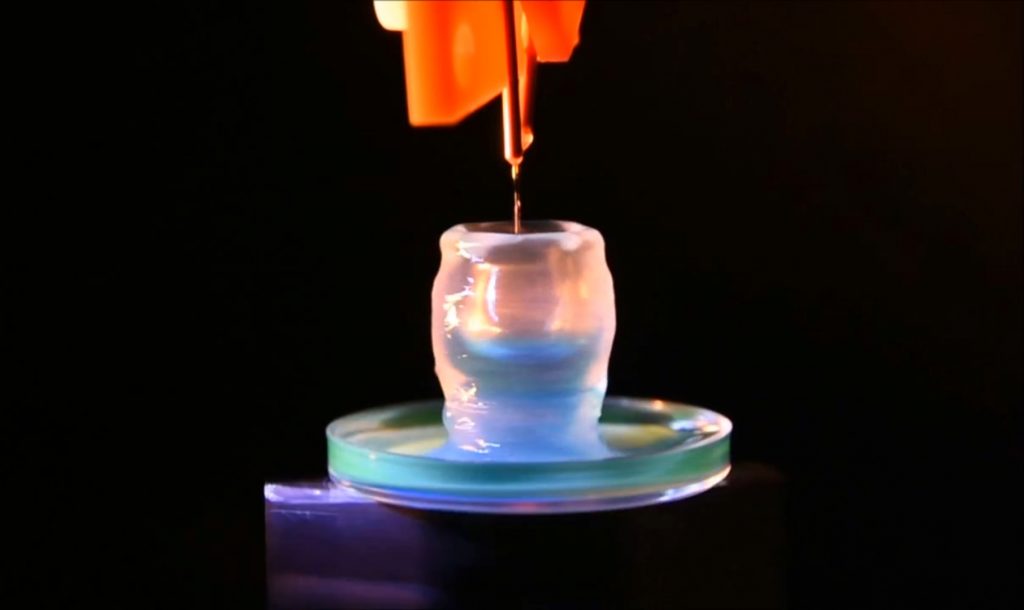

As seen the video above, in the UT setup a petri-dish spins on a kind of “potter’s wheel.” The dish acts as a substrate for materials, and sits below two pin-sized nozzles that make the machine’s print head.

Each of the pins is loaded with a different material, one that solidifies on contact with air, and the second a substance to be encapsulated. For demonstration purposed, the encapsulated substance is a CaCl salt, but the vision is that this could be replaced with, for example, a cell-laden ink.

Jetted at high speed from each of the nozzles, molecules of each material combine in the air as it acts as a channel. Particles stick to the dish on contact wh ere they form layers to make a gelatinous free-standing structures.

The centrifugal force pushes the particles out to make a hollow tube, making a valuable “building block” for further medical research, i.e. cultivating cells into tissue.

Made in a matter of minutes

A seemingly haphazard approach, the combination of jet streams and the rapidly rotating dish creates a liquid-filled foam microstructure within the gel. The pores in this foam are microscopic, producing a scale closer to the body’s natural cell structure. By adding a mold to the spinning wheel, the researchers are also capable of making more complex 3D structures, e.g. bone.

The combined particles also offer a new potential method of making emulsions – mixtures commonly used to make cosmetic and pharmaceutical products.

If made using a solid microfluidic approach the flow rate of these products would much too slow for industrial applications, “filling a volume of a cubic centimeter would take about 1000 minutes or 17 hours” the UT release explains. “The technique that is presented now, does this in a couple of minutes.”

“In-air microfluidics enables rapid fabrication of emulsions, suspensions, and 3D modular (bio)materials” is published online in Science Advances journal. It is co-authored by Claas Willem Visser, Tom Kamperman, Lisanne Karbaat, Detlef Lohse and Marcel Karperien.