3D bioprinted skin beats manual samples in A*STAR pigment research

The article was originally published on https://3dprintingindustry.com.

3D bioprinted skin often misses pigmentation. This is because researchers need a more reliable method of 3D printing with multiple types of cells.

In a Masters thesis fr om University of Texas El Paso (UTEP), postgraduate Corinne Nicole Wittmann previously considered the possibility of 3D bioprinted pigmentation. In experiments with collagen, the 3D bioprinted samples showed positive results. However, Wittmann’s research warranted further exploration to discover whether these samples could be layered together with other skin-cell types.

Another proof on concept study, this time led by a team a the Agency for Science, Technology and Research’s (A*STAR’s) Singapore Institute of Manufacturing Technology (SIMTech), has added another layer to 3D bioprinted pigment.

Droplet-on-demand approach

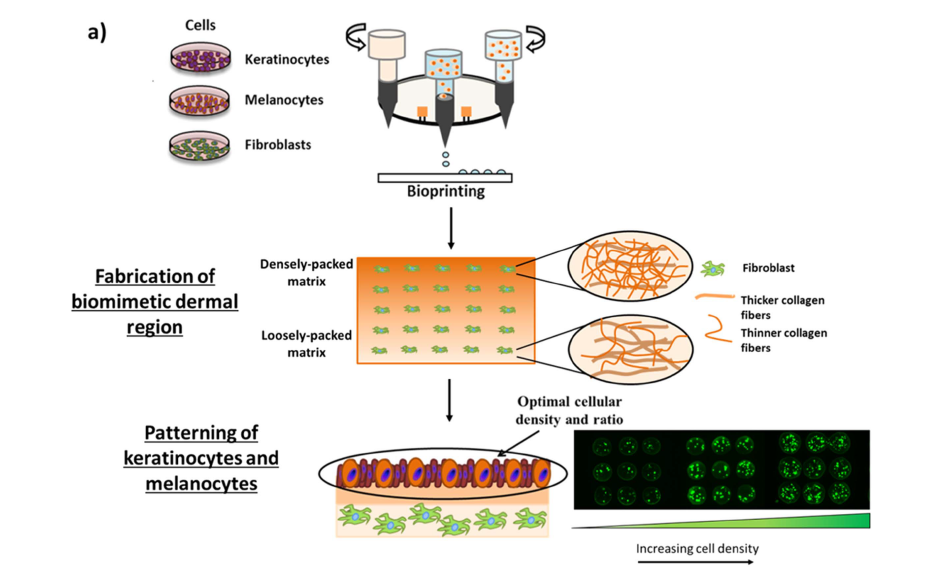

As in Whittmann’s thesis, the A*STAR approach focuses on the inkjet method of 3D printing. The main difference in the latest study however, is that the A*STAR team combines pigment cells, the melanocytes, with the two other types of structural cells needed to make the skin – keratinocytes (top layer of the skin) and fibroblasts (connective tissue).

Using a RegenHU BioFactory system, the A*Star team 3D prints cell-laden inks on a droplet-on-demand basis. Not only does this facilitate mixing between the three cell types, according to lead author Wei Long Ng, “the bioprinting technique allows the manipulation of pore sizes within the 3D collagen-fibroblast matrices, to fabricate hierarchical porous structures that are clearly seen in the native skin tissues.”

Better than the manual approach

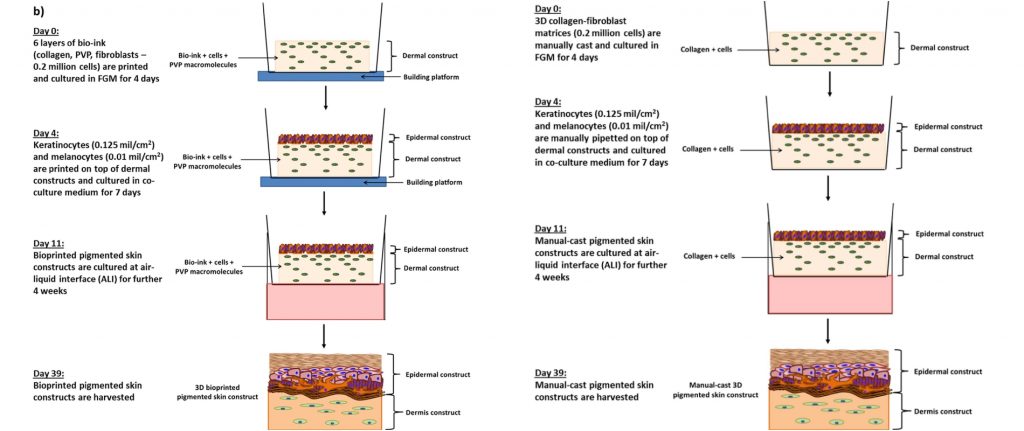

Layer by layer, skin samples are 3D printed to created a semi-solid sample. This sample is then left to culture for 39 days. Alongside the 3D bioprinted samples, the team manually casts a second set of samples for comparison.

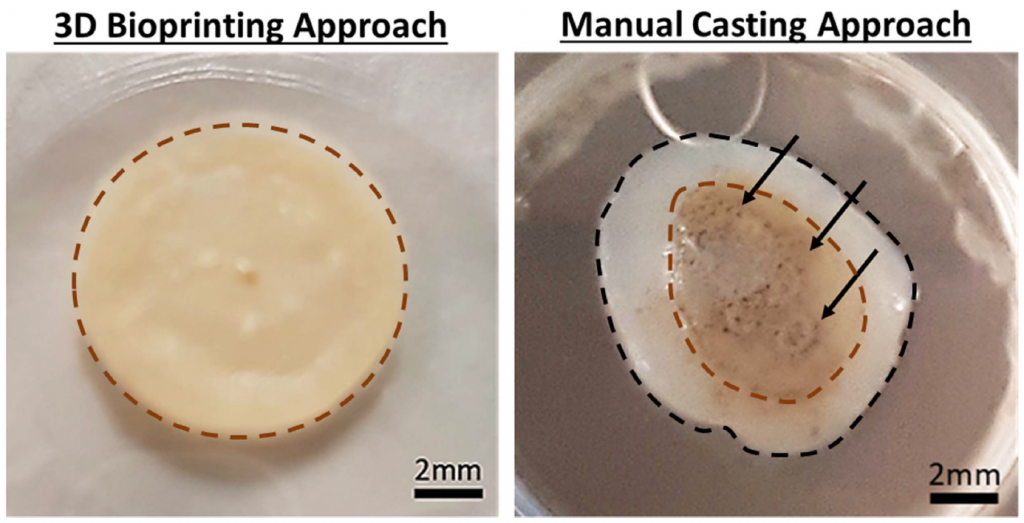

Results indicated “that the 3D bioprinted skin constructs have a higher degree of resemblance to native skin tissue” in terms of layer definition, and protein development, “compared to the manually-cast samples,” and it shows.

As explained by Wei Long Ng, “When we compared the 3D bioprinted skin constructs to those made using a manual-casting method, we found two distinct differences between the two fabrication approaches – the cell distribution on top of the dermal regions, and the microstructures within the dermal regions.”

“THE TWO-STEP BIOPRINTING STRATEGY ENABLES THE STANDARDISED DISTRIBUTION OF PRINTED CELLS IN A HIGHLY-CONTROLLED WAY, AS COMPARED TO THE MANUAL CASTING APPROACH.”

Furthermore, “tuning the skin microstructure within the 3D collagen-fibroblast matrices using the manual-casting approach is extremely challenging.”

Further research

The A*STAR team conducted the research in collaboration with the Singapore Centre for 3D Printing (SC3DP) at Nanyang Technological University (NTU). Together, the team will work towards methods of 3D bioprinted more complex and diverse skin samples to be used for “toxicology testing and fundamental cell biology research.”

The paper “Proof-of-concept: 3D bioprinting of pigmented human skin constructs”, is published online in Biofabrication journal. It is co-authored by Wei Long Ng, Jovina Tan Zhi Qi, Wai Yee Yeong, and May Win Naing.